Building a Modern Coat Rack

This Modern Coat Rack was super fun to build! It features retracting hanger and an excellent flush wall mounting system. I have seen a lot of coat rack and hat rack videos out there but nothing quite like this. I designed this piece to look like a piece of art rather than just a board on the wall with homemade dowels supporting the hidden hangers.

I used black walnut for this piece, and it really looks like one solid piece when hung on the wall. The walnut also has a great warmth to it that fits, being that it is a coat rack. And the angles are subtle but purposeful. The hangers work great too, and the flip-down motion makes them hideaway well when not in use.

As I said, I have seen other coat racks that give the impression of being one piece, but none really took it to this level where it really is just one piece. This one is much more monolithic in its style. I had a really great time with this whole process. If you have any questions about the build, please leave them in the comments below, and I will happily answer them. Enjoy the build!

Project Plans: https://bit.ly/tbwcoatrack

Supplies

Your Choice of Hardwood (I used 8/4 Walnut)

Table Saw

Bandsaw

Sand Paper

Sanding Block

Finishing Oil

Locking Wall Mount

You can find the full-scale templates here:

MILL LUMBER AND CUT TO LENGTH

Mill the lumber using a jointer and planer.

Because the lumber was too wide for my jointer, I hot glued some shims to a piece of plywood to make a sled for the planer.

Then, I ran the board through the planer with the flattened side down.

Square the edge back at jointer.

Using a table saw with the jointed edge against the fence, rip the board to 2.5".

Plane the board down to 1.5"

Rip the board to it's final thickness of 2 3/8".

Using a crosscut sled, square off one end.

Mark the location of the final length and cut the board using a crosscut sled.

MAKE DOWEL HOLES AND CUT DADO

Mark the location for the dowel holes.

These need to be done now for the holes to be square.

Use a drill press and brad point bit to drill the holes.

Then, layout the dado cut with a t-square.

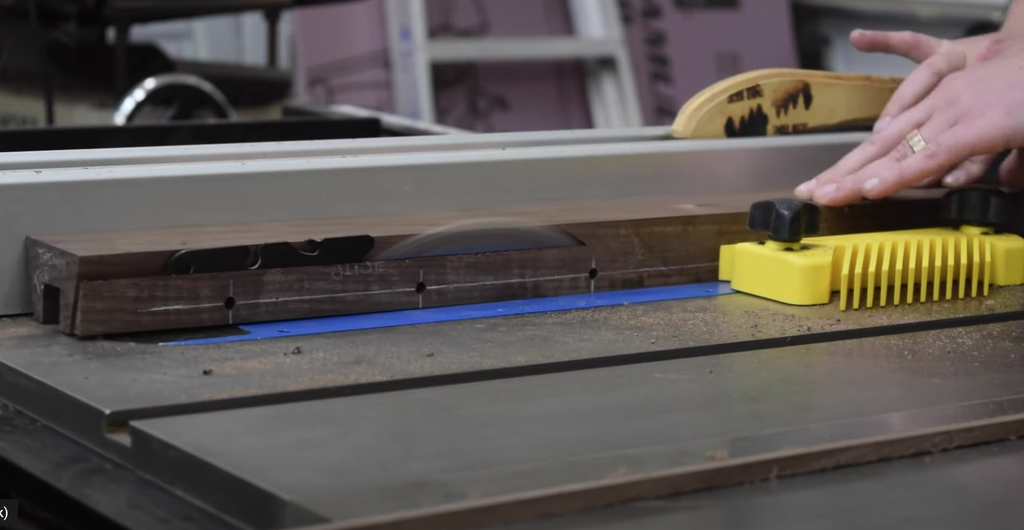

At the table saw set the dado depth. Then use a feather board to keep the workpiece flush to the fence while you cut in the dado.

I did this in 3 passes, only moving the fence for the third clean-out cut.

ADD THE BEVELS AND BACK ANGLE

Set your ripping blade to 75 degrees.

With the with the dado face down, rip a bevel along the edge of the piece.

Flip the piece around and cut the bevel along the other side.

Tape the offcuts from the bevels onto the workpiece and build a sled.

This allows for the taper to be square and gradual - letting jackets hang more staggered.

Cut the back angle at the table saw.

MAKE THE HANGERS

Square off the edges of another piece of lumber using a crosscut sled.

I used what was left over from the same board as the frame.

Using a bandsaw, cut a taper along the length.

Using a tenoning jig at the table saw, cut an angle for the hanger to tilt flush on when extended.

Set up a stop block on the crosscut sled and cut the hangers to be the exact width of the earlier cut dado.

Mark the dowel hole placement with an awl.

Drill the dowel holes using a drill press or drill.

Test fit each hanger to ensure they fit flush with the frame.

MAKE THE DOWELS

Cut a strip of wood just over the dowel hole size.

Chuck the piece into my drill and rounded off the edges with sandpaper.

Use a dowel making jig to cut the dowels to their final diameter.

Check for a snug fit and made sure the hangers functioned correctly before gluing them in

SANDING AND FINISHING

Sand the hangers, breaking the edges on the backside only.

I used some spray adhesive to attach a sanding disk to a plywood board for this.

Clamp the frame down and sand away the cut marks left in the dado from the table saw.

Apply finish to all of the pieces.

Getting to the hangers and dado later would be difficult, so I applied finish to them prior to gluing in the dowels.

Once the finish is dry, glue in the dowels.

Only applying glue to the outside hole, then the dowel just before pushing it in.

Then use a flush trim saw to cut away the excess.

Sand the dowels flush with a sanding block.

Finish the rest of the piece with oil.

Use locking wall hangers to mount the rack to the wall.

All that's left is to hang the test out the hangers with some coats!

The approximate cost for building this coat rack as designed with all of the bells & whistles is about $60 (this will, of course, vary for everyone).

Tag me on social if you're building this project (@timberbiscuitwoodwork on Instagram) with the hashtag #BiscuitBuild - Happy building!