Building a Crosscut Sled

Okay, so it was about time that I made a few upgrades to my workshop since I hadn’t done any in a while. One of the first things I wanted to do was to make a big crosscut sled! There are tons of advantages and one of them is that you can cut wider material but this also allows for longer cuts as well. I also made it this size to accommodate full-length cabinets!

Supplies

3/4" and 1/2" Baltic Birch Plywood

Table Saw

Wood Glue

Clamps

Hardwood for Runners

Drill

5/8" Screws

CA Glue

CUT DOWN PLYWOOD

For the Base:

First I had to cut down my sheet goods. For this crosscut sled I'm using 3/4" baltic birch plywood. I went with 27" by 48" for the base of the sled.

For the Fences:

Next, I took the fence material and I ripped it down into three different pieces. One side note, I did switch to half inch baltic birch for the front fence just to lighten the sled and give me a little bit more space - and leave us enough room to cut full length cabinets!

I ripped the fence pieces down to 3" in width.

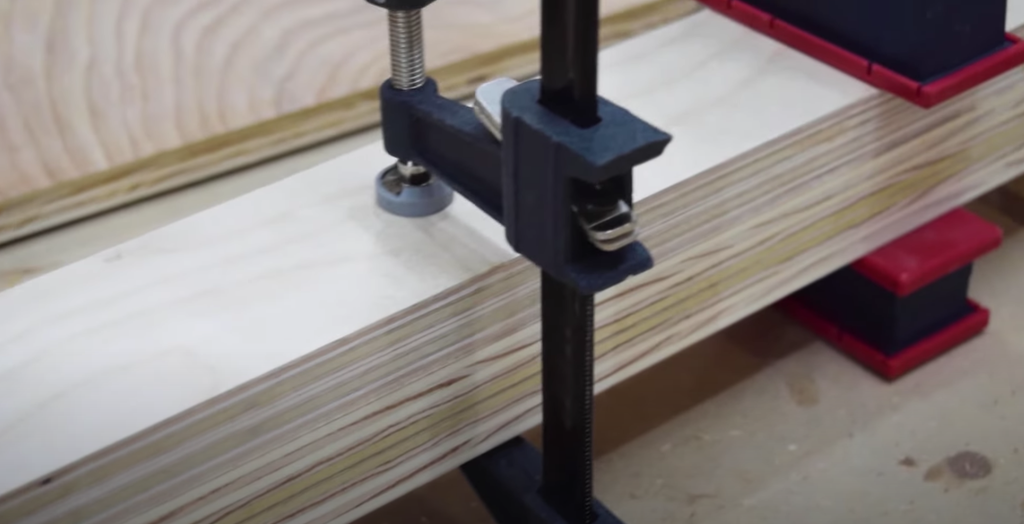

GLUE UP THE FENCE

Next I applied some glue on both sides of our pieces and used a brayer to spread that glue out. Then I threw them into the parallel clamps and clamp them up. Another note, this front fence is a little bit shorter than the rear fence just because it doesn't need to be all the way across - this will save myself some weight from having to move this thing around in the shop.

CUT ANGLES AND CHAMFERS

With the glue dry, I removed the clamps and put a 45 degree angle on the top corners of each fence. This is more for aesthetics and just so I don't nick myself on the corners.

From there, I brought the fences over to the router table and put a 45 degree chamfer on the sides that i would be touching as well as the side that faces the blade. Doing this prevents sawdust from clogging the fence and throwing off the work piece as we're cutting.

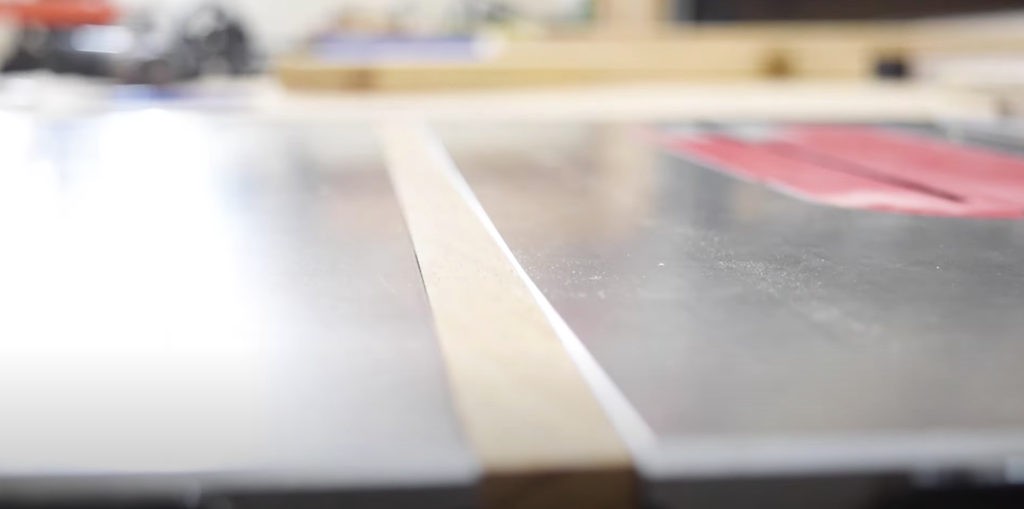

MAKE THE RUNNERS

I used white oak for the runners and I made sure that I have the grain direction running vertically. This way it doesn't swell in the miter slot and get stuck and expand with humidity over time. Check your saw's miter slots for the dimensions as these vary from saw to saw.

Because this sled is so large it won't fit against my fence so I clamped a square to the edge so that I had something to reference against when attaching the runners.

I used a few pennies in the miter slots to flush the runners up against the top of the table so I could glue them to the sled. From there, I applied some CA glue to the runners and some activator to the bottom of the sled then firmly pressed the two together for about 10 seconds. It you're not in a rush you could go for 20 seconds.

Last, I pre-drilled and drove in a few 5/8" screws, about 5 for each runner.

ATTACHING AND SQUARING FENCES

Next, I carefully raised the blade through the sled taking care not to cut all the way through the rear of the board! I stuck an eighth inch piece of scrap into the slot and used the largest square I have to roughly square up the fence. This doesn't have to be perfect right now we'll dial it in here in a minute.

Next, I pre-drilled and drove one screw into each end of the fence and fully attach the front fence. This will secure the fence while we do the fine adjustments.

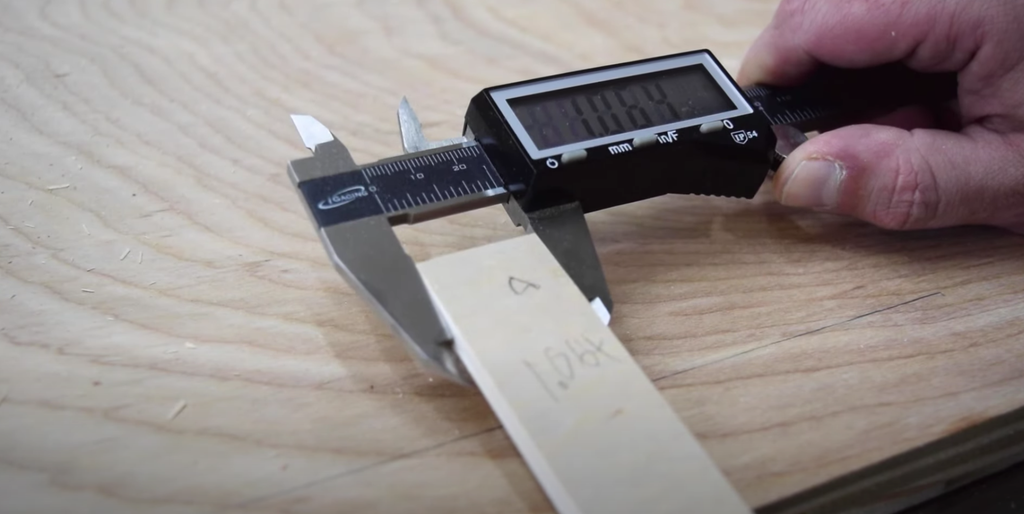

To dial the fence in I used the five cut method. Here is a link the the calculator for it: https://bit.ly/5cutmethod

With my adjustments made, I reattached the fence drilling the screw into a new hole and redoing a test cut. With a deviation of three thousandths over 44 inches, I called it good!

Then I applied a thin coat of paste wax at the bottom of the sled and the runners and now I have a really large crosscut sled that's square and can handle some really large work pieces!

Tag me on social if you're building this project (@timberbiscuitwoodwork on Instagram) with the hashtag #BiscuitBuild - Happy building!